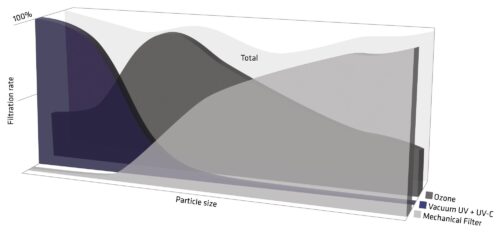

Differences in used cooking methods and other kitchen devices as well as grease, humidity, and other airborne impurities set great demands for the cleaning of professional kitchen exhaust air. In most cases, relying on a singular cleaning technology is not sufficient for attaining a high enough filtration rate. This highlights the need for solutions that combine several complementary cleaning technologies, each contributing to a different aspect of air cleaning.

Mechanical filtration / impact filtration

Mechanical filtration efficiently filters out large grease particles resulting in the cooking process. The heavy particles are sieved out of the extract air that travels through an impact or a cyclonic filter. This is a widely used method in the kitchen hoods. However, it is inefficient against smaller grease particles.

UV-C

UV-C is a commonly used, conventional “germicidal” cleaning technology. It uses longer wavelength of 254 nm ultraviolet light that actively works against micro-organisms, molds, fungi, and bacteria.

Vacuum UV

For further refining the filtration rate of professional kitchen ventilation, a shorter wavelength ultraviolet light can be used. Vacuum UV is highly efficient in dissolving small grease particles into natural compounds, such as oxygen, carbon-dioxide, and water.

In addition, vacuum UV provides a significantly high UV intensity. It has proven to be the only way to keep the extract air ducts clean. The dissolving rate is identical to water cleaning system.

Ozone

The combination of mechanical filtration and two different wavelengths of UV light yields high results. The overall filtration rate can be enhanced using ozone. Ozone is naturally produced in the photochemical reaction, where ozone effectively dissolves whatever is left of the grease particles and deodorizes air in the ducts.

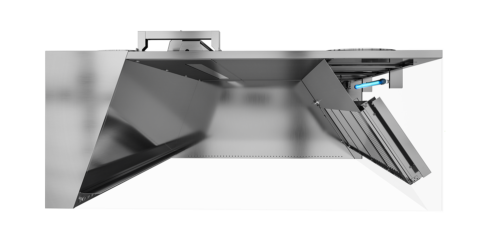

CleanMaster combines all four cleaning techniques

Climecon was among the first manufacturers to provide safe and efficient UV cleaning technology for professional kitchen conditions. Safety is our top priority, and CleanMaster solutions are equipped with two-fold safety-mechanics. Our hood and ceiling ventilation solutions are praised for their long-lasting impact. And this is why, after two decades, CleanMaster continues as the choice of kitchen professionals.