1) Two different UV wavelengths are needed for the highest cleaning efficiency

UV-C is a commonly used, traditional cleaning technology that prevents bacterial growth. It uses ultraviolet light of a longer wavelength (254 nm), which effectively works against micro-organisms, molds, fungi, and bacteria. Vacuum UV, on the other hand, breaks down small fat particles very efficiently and produces ozone to further enhance air purification and odor removal. The combination of the two UV lights is necessary for reaching clean extract air.

2) With efficient UV technology, the ductwork and grease chamber remain clean

The cleanliness of the ductwork and grease chambers is essential for the property’s fire safety and for managing maintenance costs. We often hear that thanks to our UV hoods, sweeping has not been needed once during years of service. One example is a vocational college in Helsinki, which has more than a hundred CleanMaster hoods, and the site’s ducts have not had to be swept since the commissioning back in 2017.

Double UV intensity with lamps developed for professional kitchens

Fat dissolvance requires 50 mW of UV intensity per square centimeter. This breaks up the airborne fat particles in the exhaust air chamber and on its inner surfaces. Dual UV lamps are the most efficient on the market and can produce vacuum UV light at 25 W. The combination of the two UV wavelengths (Vacuum-UV and UV-C) in Dual UV lamps is proven to be twice the intensity of similar systems on the market.

3) Long-lasting lamps require fewer replacements

Investing in the long service life of UV lamps pays off when control over professional kitchen maintenance costs is sought after. Maintaining a high UV intensity throughout the lamp life is also important, as it is a critical factor in the hood’s air purification ability.

Dual UV retains more than 96% of its original UV intensity for up to 16,000 hours. Dual UV lamps must be changed only half as often as similar lamps. In addition, only one UV lamp is needed per hood, and not two, as in other available systems. Especially in larger kitchens, the number of UV lamps as well as their replacement interval have a significant impact on maintenance costs.

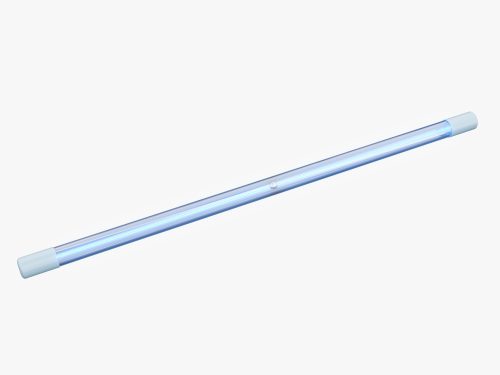

Dual UV kitchen pro lamps

Dual UV kitchen pro lamps

- Resistant to high temperatures up to 100 ˚C

- Extra thick glass can withstand impacts

- Quick connectors speed up installation and maintenance

- Cleaning-free

- 16 000 h service life